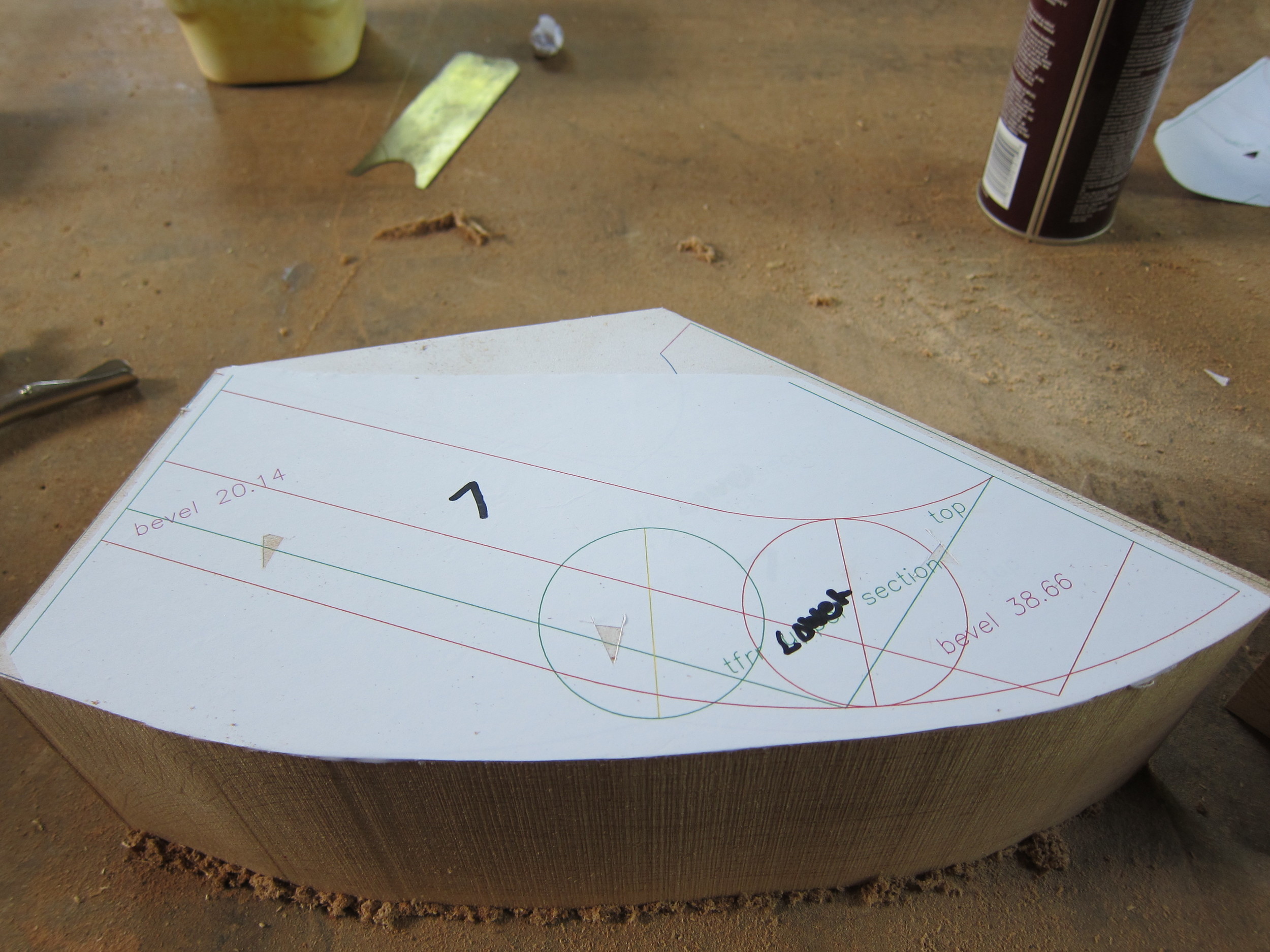

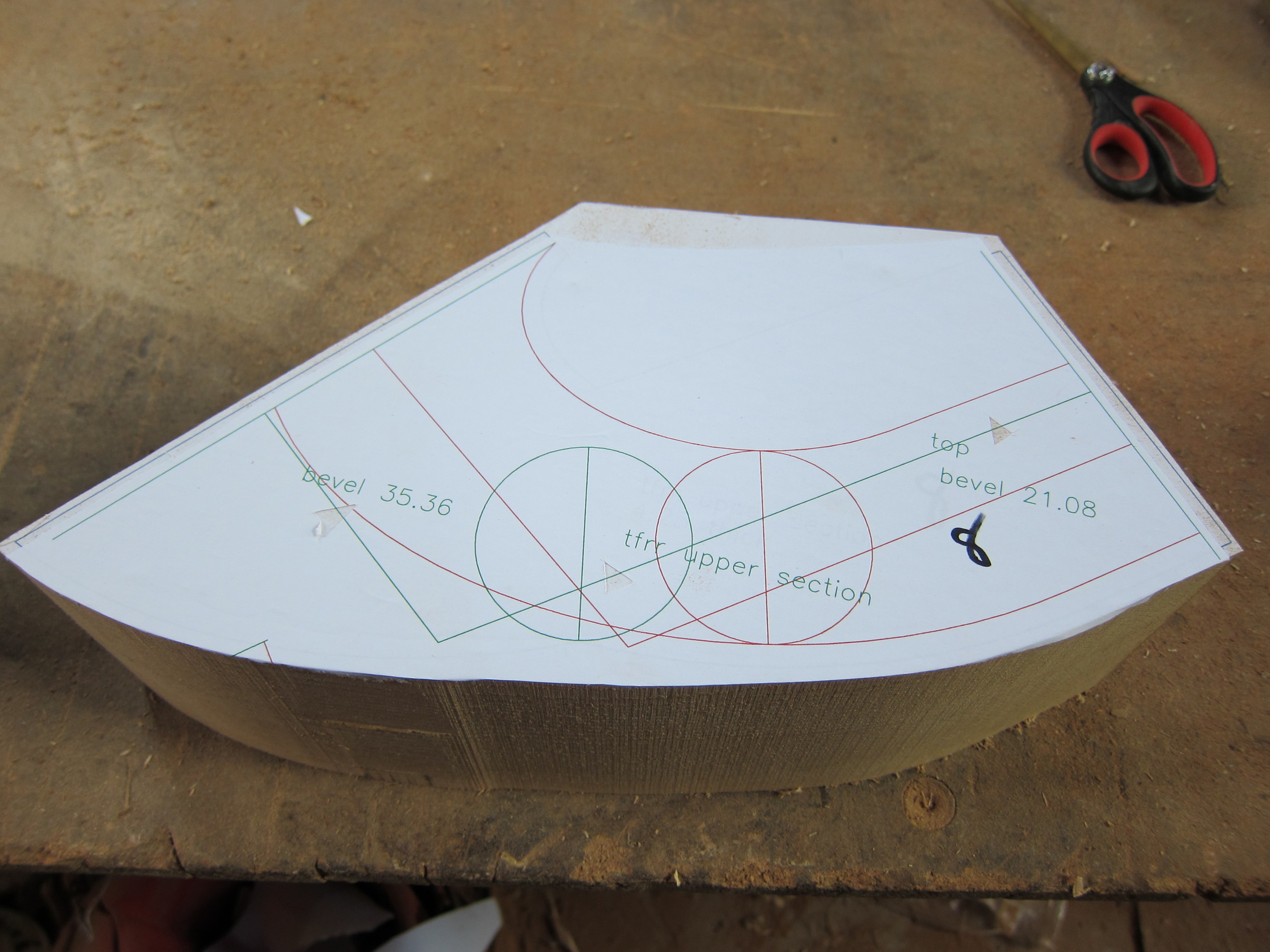

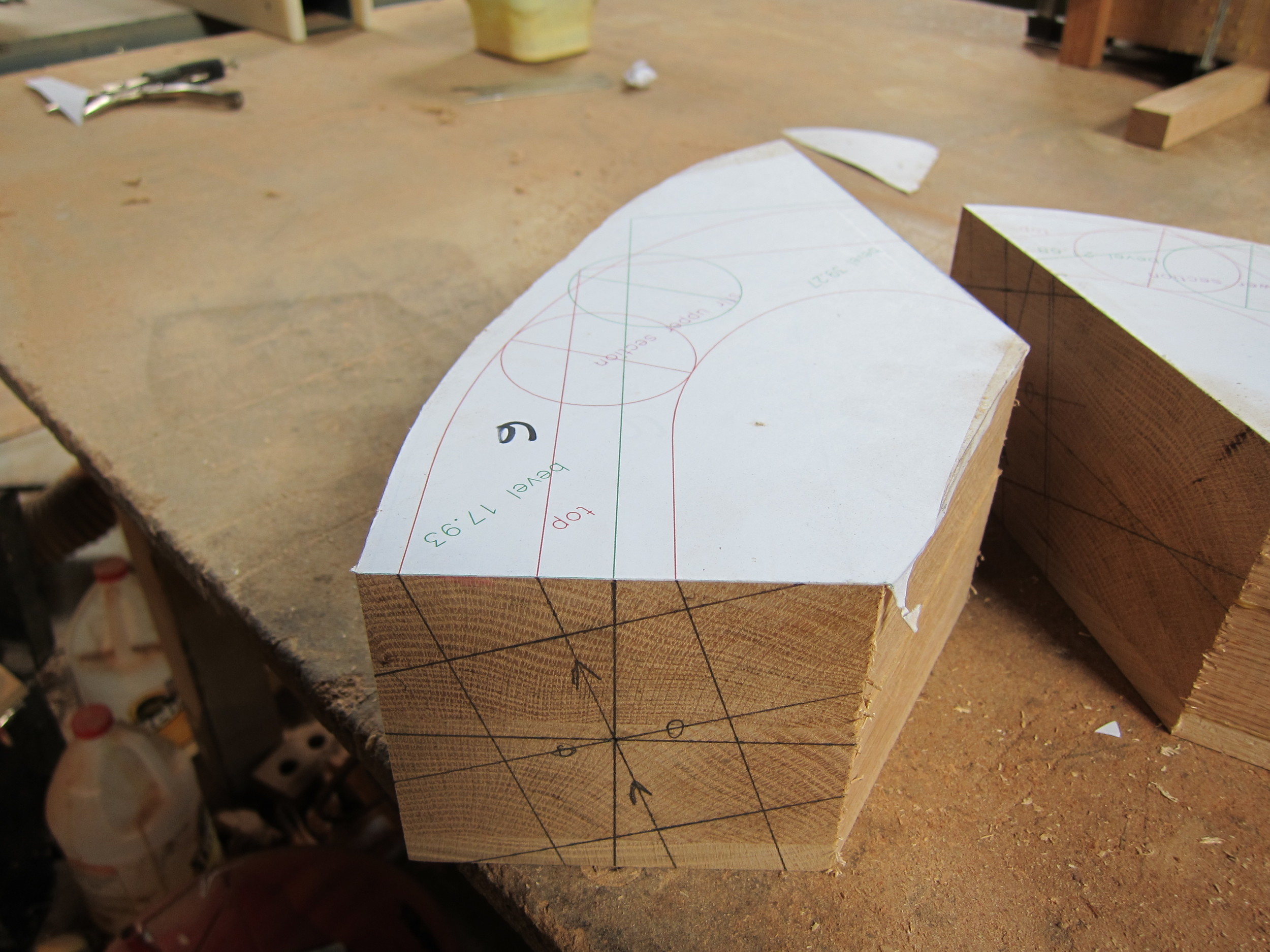

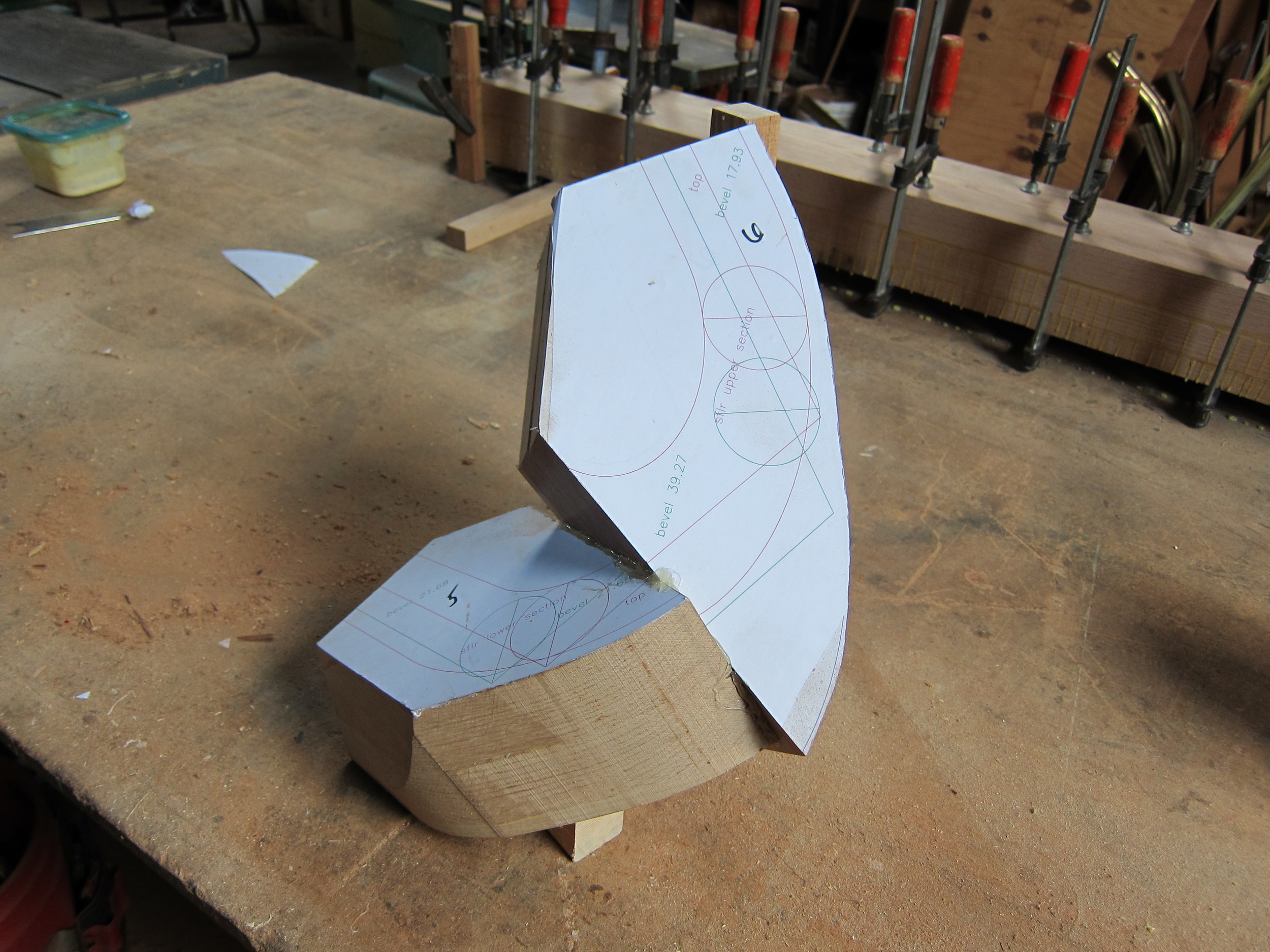

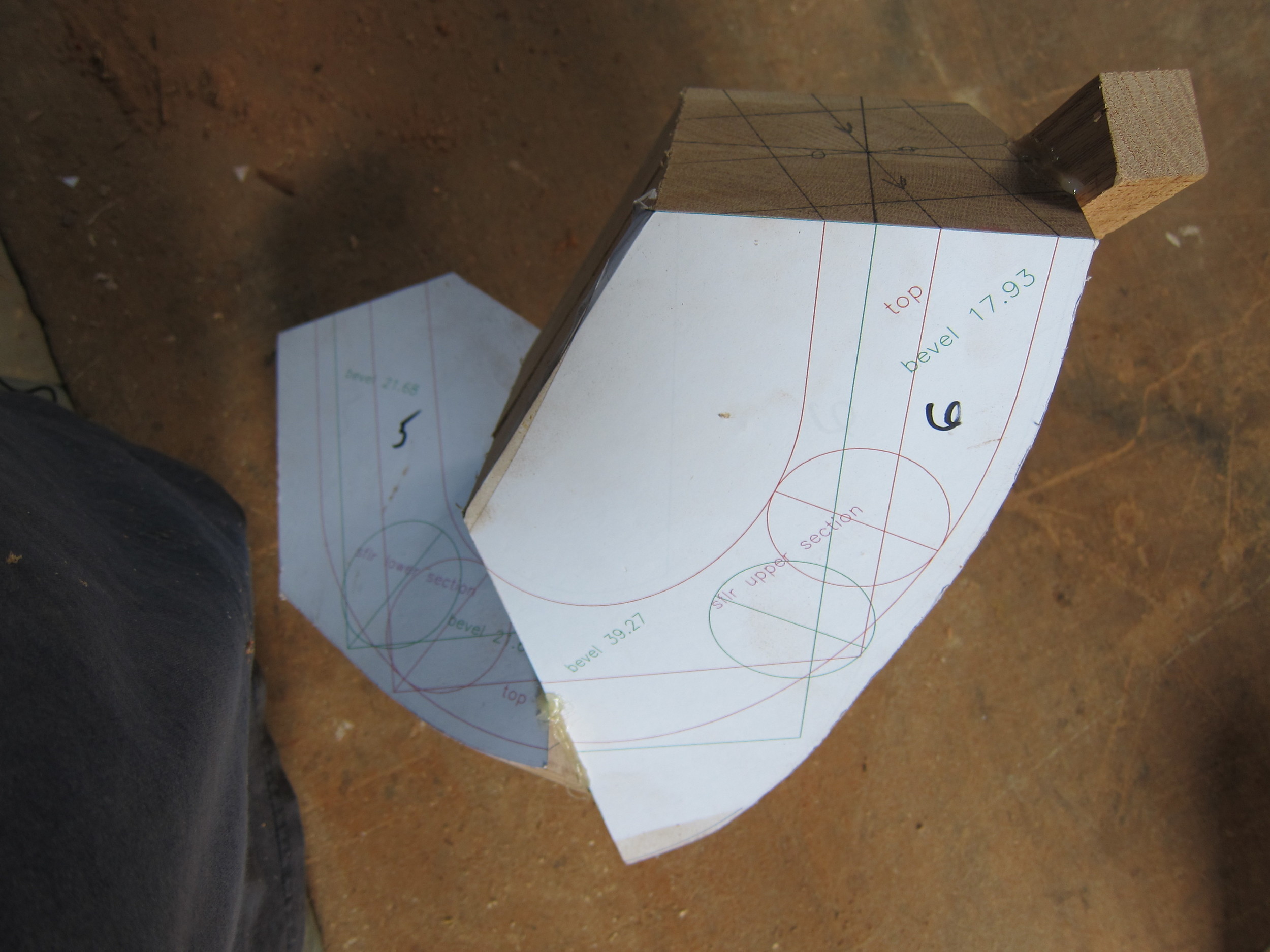

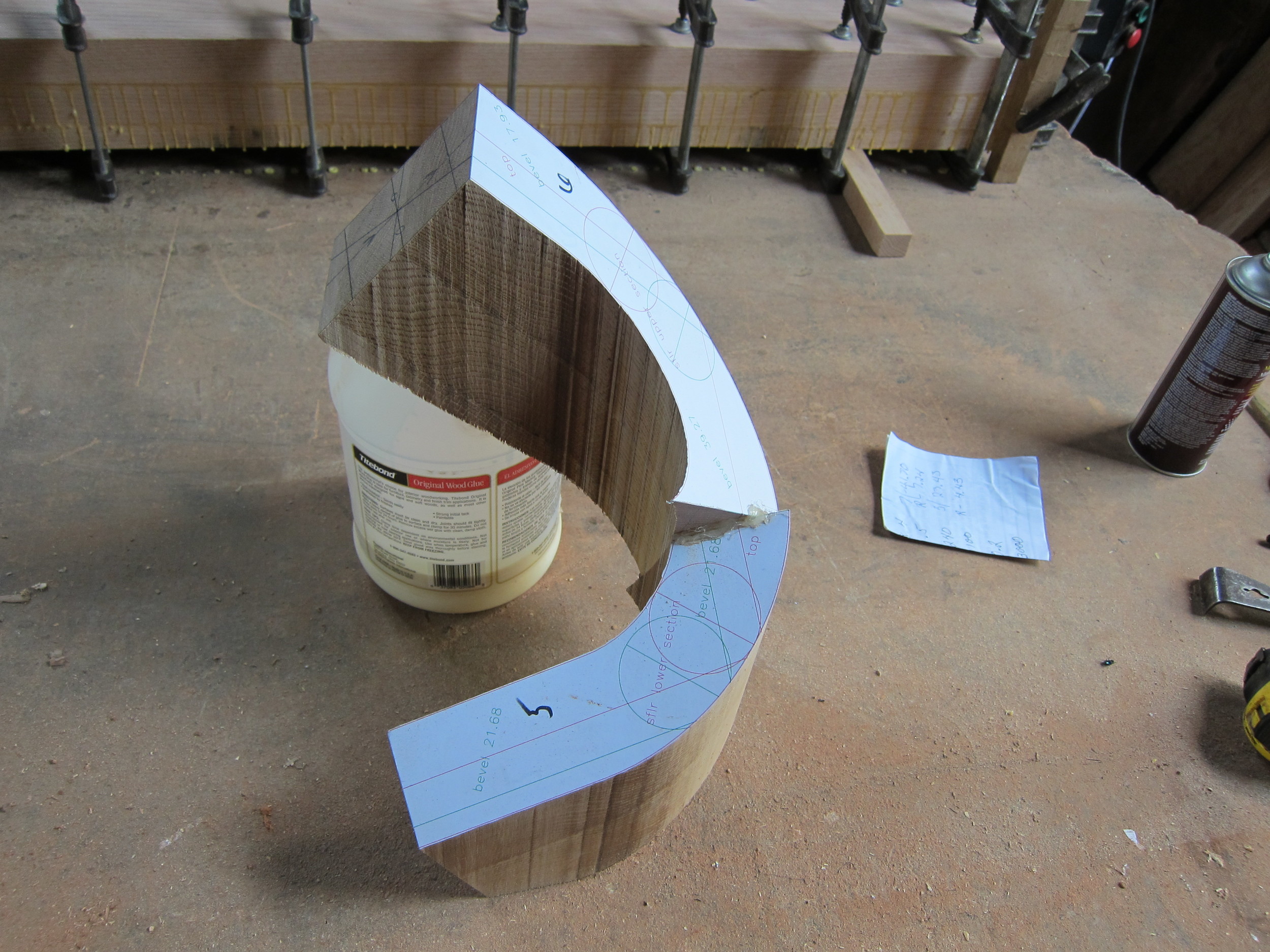

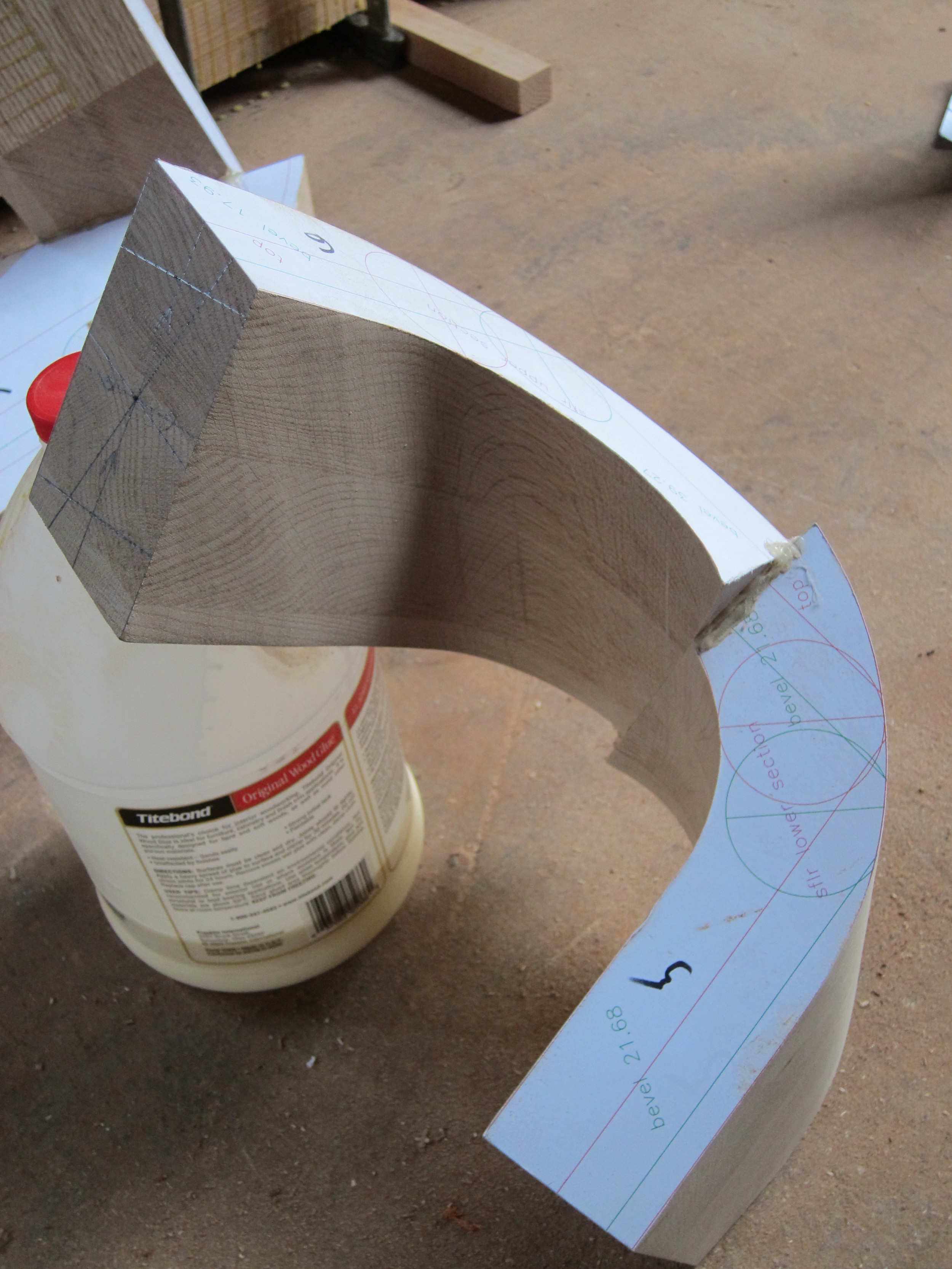

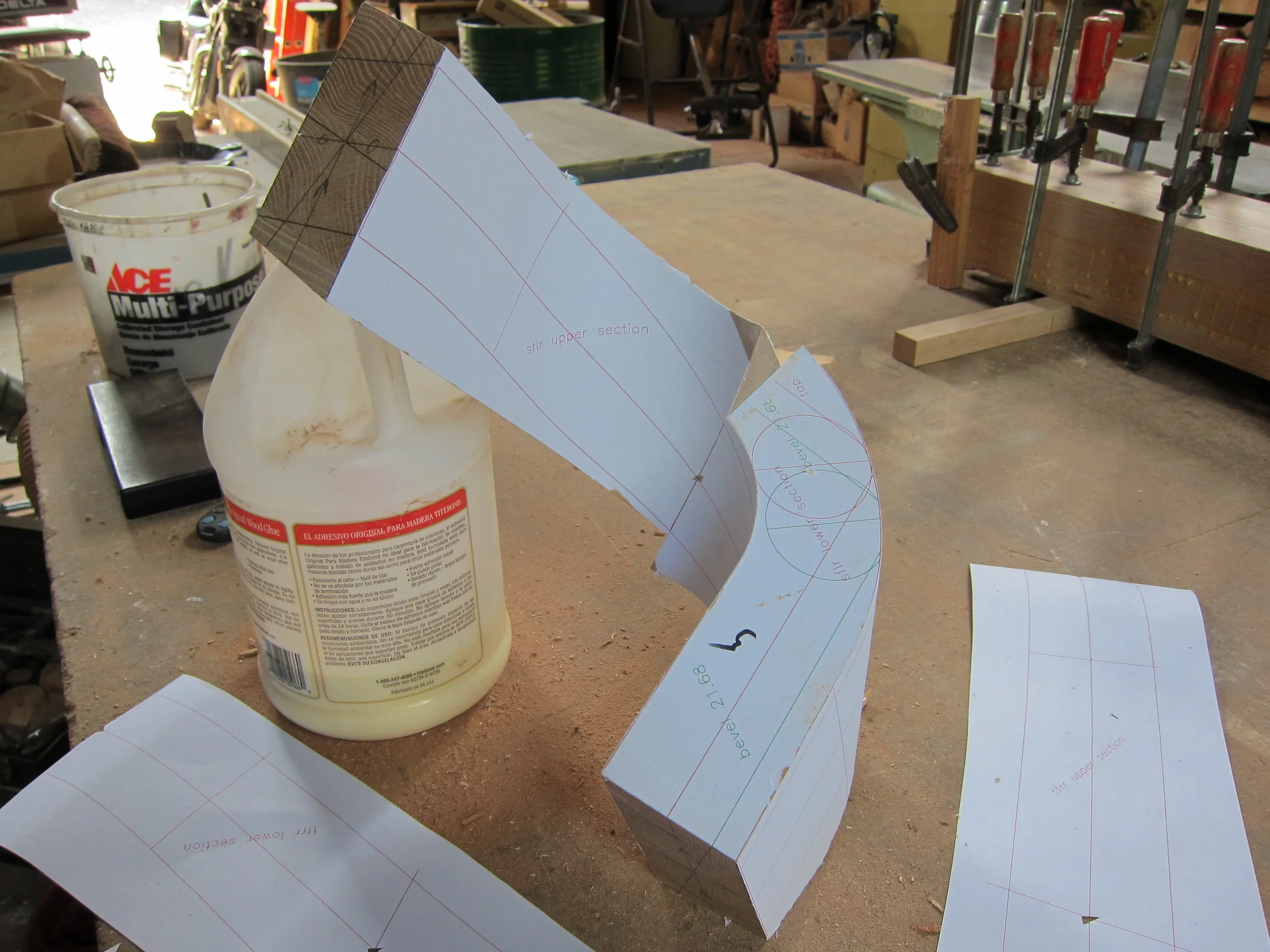

The process begins with a drawing of the stair in plan and elevation with center line of rail and joint lines. From here we go to the the cad program on the computer using the "tangent method" to begin the process of obtaining patterns or molds to apply to our wood to guide us in the proper cutting out of our handrail. Once the face molds and falling molds are drawn, I print them out full scale with a plotter and spray glue them onto my block of wood.