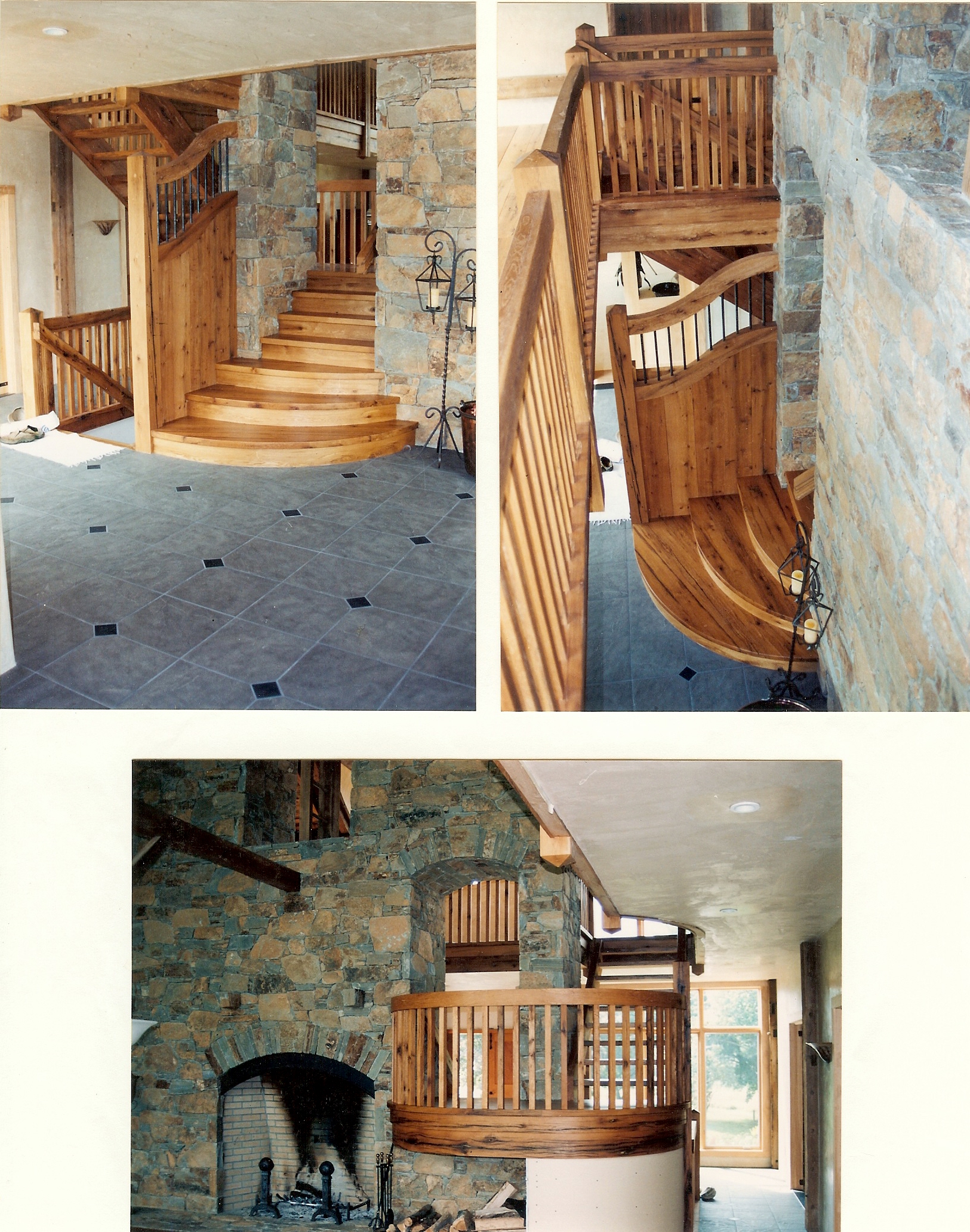

The rest of the puzzle came soon after I made contact with my old partner in business. Unbeknown to me he had been pursuing the same handrail process. The only difference being that he found someone who was well established in the old world handrail techniques and was willing to share what he knew, including the shaping process. The shaping or profiling process which he shared with me was a key element for making the whole handrail process practical and I used this method for years. The down side was that it was very dangerous and eventually I almost lost my thumb, so I began looking for a safer, affordable, way to shape the handrail. A five axis cnc machine will do the job nicely but was not affordable, but a three axis machine with a 4th axis indexer was my next adventure. Communicating with a machine requires you to speak the language which in my case meant learning 3D cad and a cam program to write the tool paths. Now I am applying the old world ideas of laying out handrail with the help of modern technology in 3D cad, and using a cnc machine for the actual cutting which makes for a safe and accurate, beautiful end product. I have successfully sent handrail components from Pennsylvania, all over the USA, as far as the state of Washington, Idaho and Alaska.

This is my story and the passion behind Custom Handrails. Maybe you have a project you are considering and desire something beautiful and different that can't be bought at the big box stores. If you are not afraid of an investment, let me show you how to produce a timeless centerpiece of beauty in your home.